Overview

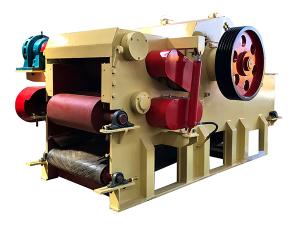

Our wood log debarker or wood log bark peeling machine, is used for peeling off the bark of the tree. This machine is newly designed to improve the working function.

Features of Wood Log Debarker

1. The open silo and assembly line operate by feeding the log from one end to the other, discharging at the other end. The machine features high working efficiency.

2. Due to the teeth, a rotor that features debarking teeth in a ladder design strikes the log, the log is moved in a circular, rotational motion to ensure complete bark removal.

3. The machine is applicable to different wood types, as well as logs of varied diameters, lengths, shapes, and even bent logs.

4. As the large main frame remains still, the bark removal machine ensures low energy consumption, low failure rate, easy maintenance, low vibration and low noise. It is easy to install and operate, which can be done without pedestal mounting.

Application of Wood Log Debarker

The bark removal machine has been designed to peel the bark from wood, and is applicable to nearly all wood types, especially eucalyptus and aspen. It is often the first choice in replacing other debarking methods, and acts as accessory equipment for assembly line work. It is widely used in MDF factories, paper making plants, veneer rotary cutting factories, wood chip factories, paper pulp factories, wood storage factories and forest farms.

| Type | HX-S300 | HX-S400 | HX-S600 | HX-S800 |

| Wood diameter (mm) | 50-300 | 50-400 | 200-600 | 400-800 |

| Wood length (m) | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 |

| Capacity (T∕H) | 6-8 | 8-10 | 10-12 | 15-18 |

| Debarking rate (%) | Fresh log >95% Dry log > 90% | Fresh log >95% Dry log > 90% | Fresh log >95% Dry log > 90% | Fresh log >95% Dry log > 90% |

| Roller diameter (mm) | 275 | 377 | 530 | 710 |

| Roller rotational speed (rpm) | 230 | 200 | 200 | 180 |

| Roller length (mm) | 5000 | 5000 | 5000 | 5000 |

| Power (kw) | 7.5 x 2 | 11 x 2 | 15 x 2 | 30 x 2 |

| Weight (T) | 3.5 | 3.5 | 5.5 | 8 |

| Size (L x W x H) (m) | 6 x 1.6 x 1.55 | 6 x 2 x 1.6 | 6 x 2 x 1.8 | 6 x 2.5 x 2 |

Advantages

1. Two debarking rollers ensure a high debarking rate and capacity.

2. Assembly line work is carried out by feeding to one end and discharging at the other, ensuring high work efficiency.

Optional Configuration

1. Capacity: 6-8T/H, 10-12T/H, 15-18T/H

2. Power: 7.5 KW x 2, 15 KW x 2, 30 KW x 2

Brief company

Hongxing is a wood log debarker manufacturer, the debarker is used to peel the bark from the log. The bark peeling machine is essential equipment for paper mills producing pulp and paper, it is ideal for business in the plywood or engineering wood sectors. Hongxing offers a wide range of machines and equipment for bio-industry sectors, like biomass, compost, biofuel and biogas. We are a trustworthy company producing bio-machines for bio-equipment users.