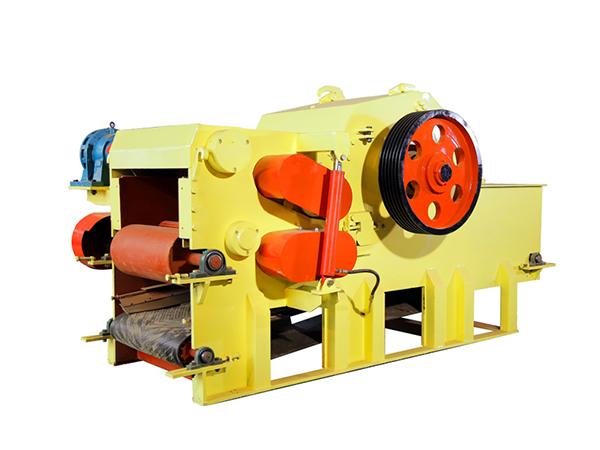

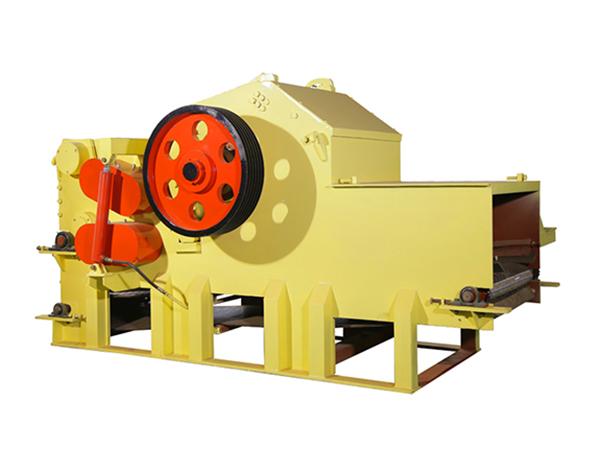

Overview

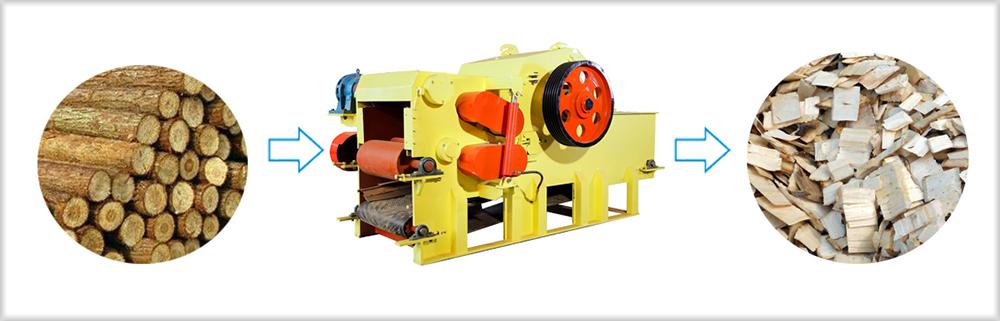

Raw material for mobile drum wood chippers usually consist of undersized logs, wood cutting residue (such as branches and logs), wood processing residue (slabs, battens, wood cores and waste veneer) and non-wood material (such as flax, cotton stalk, reed and bamboo waste).

They are known for the following:

1. Advanced structure and reliable technology

2. High throughput capacity and high quality chips

3. Low-maintenance and environmentally friendly

4. Cost-efficient and space-saving

5. Chipping of all kinds of wood

6. Guaranteed long service life

7. Hydraulic control, simple operation, easy maintenance.

Application

Drum wood chippers are specialized equipments used for producing wood chips in wood factories and are widely used to prepare raw material in chipboard plants, fiberboard plants, and paper making plants.

Advantages

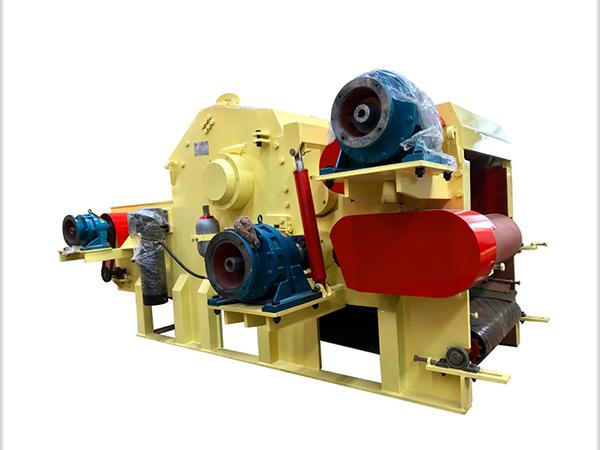

Hydraulic system

1. Open the rotor upper cover to inspect, repair and replace the blades or hammers.

2. Overturn the rotor cover to inspect, repair and replace the screen.

3. Pressure regulation to adapt to wide raw material usage and protect the main motor.

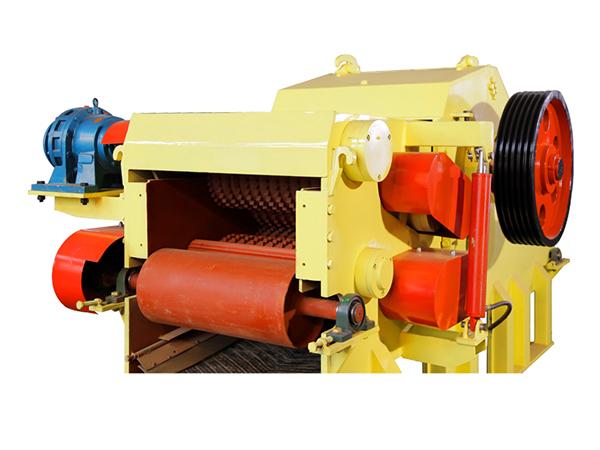

Feeding Roller

A tooth feeding roller easily bites into the raw material so that feeding is done quickly and smoothly, ensuring high output quality.

Screen

Control output size. The oversize wood chips can not come out of the machine and will be chipped again till to be qualified size.

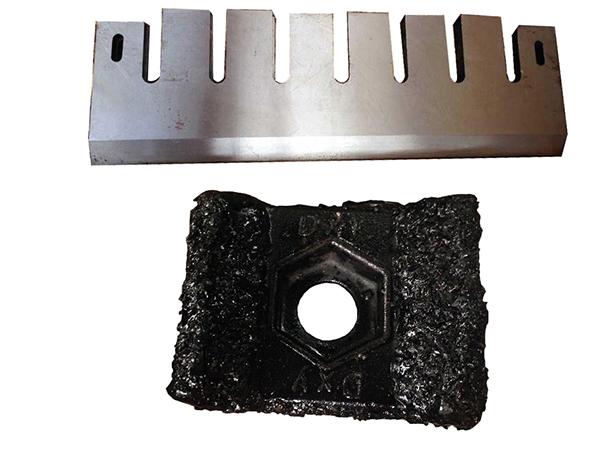

Durable cutting devices

Material of blade is H13 Alloy or A8 Alloy.

Material of cutting part of hammer is TY115 Alloy.

Optional Configurations

1. Cutting device quantity

2. Input size

3. Capacity

4. Main power

5. Wood chip length

| Type | HX216 | HX217 | HX218 | HX426 | HX428 |

| Rotor diameter (mm) | 650 | 650 | 800 | 650 | 800 |

| Cutting device quantity (piece) | 3 blades or customized | 3 blades or customized | 3 blades or customized | 20-35 hammers or customized | 20-35 hammers or customized |

| Screen size | Φ 50 or customized | Φ 50 or customized | Φ 50 or customized | Φ 60 or customized | Φ 60 or customized |

| Input size (mm) | 540x240 | 680x240 | 680x310 | 1250x250 | 1250x310 |

| Blade rotational speed (r/m) | 590 | 590 | 650 | 600 | 650 |

| Rate of feeding (m/min) | 38 | 38 | 35-38 | 38 | 38 |

| Max material diameter (mm) | 220 | 220 | 300 | 240 | 300 |

| Wood chip length (mm) | 30-50 or customized | 30-50 or customized | 30-50 or customized | 30-80 or customized | 30-80 or customized |

| Capacity (t/h) | 6-8 | 8-10 | 10-12 | 8-10 | 10-12 |

| Main power (kw) | 55 | 75 | 110 | 110 | 132 |

| Feeding motor (kw) | 3+4 | 3+4 | 5.5+4 | 5.5+5.5 | 5.5+7.5 |

| Discharging motor (kw) | 3+3 | 3+3 | 3+3 | 5.5+5.5 | 5.5+5.5 |

| Oil pump motor (kw) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Feeding conveyor length (mm) | 4000 | 4000 | 4000 | 4000 | 4000 |

| Discharge conveyor length (mm) | 10000 | 10000 | 10000 | 10000 | 10000 |

| Weight (t) | 4.5 | 5.8 | 7 | 8.2 | 10.4 |

| Delivery | 1x40'GP | 1x40'GP | 1x40'GP | 1x40'HQ | 1x40'HQ |

Inquiry Tips

When send us inquiry, please try to tell us the following information:

1) What is the raw material?

2) What is dimension of raw material?

3) What is moisture of raw material?

4) What is output wood chips size?

5) What is production capacity per hour?

6) Fixed type or mobile type?

7) Is power electric motor or diesel engine?

8) What is Voltage and Frequency of your local industrial power?

This will help us to offer you a suitable model.

Overviews

Disc wood chipper is effective in producing uniform wood chips for paper mill, MDF board plant etc.

Application

Disc wood chipper converts wood logs, branches and wood cutting residues into useable wood chips for preparing raw material for density board plant and paper-making plant, etc.

Advantages

Optional Configurations

1. Blade quantity

2. Input size

3. Capacity

4. Main power

5. Wood chip length

| Model | HX1710 | HX1212 | HX1300 | HX1112 | HX1216 | HX1800 |

| Rotational speed(rpm) | 635 | 635 | 650 | 650 | 620 | 420 |

| Blade QTY(piece) | 6 | 6 | 6 | 6 | 6 | 6 |

| Chip size(mm) | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 | 20-35 80-100 |

| Input size(mm) | 270x270 | 320x320 | 350x350 | 400x400 | 420x420 | 500x500 |

| capacity(TPH) | 5-10 | 10-15 | 13-18 | 15-18 | 15-25 | 20-40 |

| Main power(kw) | 55 | 90 | 90 | 110 | 160 | 160 |

| Feeding + discharging motor (kw) | 3+3 | 3+3 | 3+3 | 3+3 | 3+3 | 5.5+5.5 |

| Disc diameter (mm) | 1150 | 1300 | 1300 | 1300 | 1600 | 1800 |

| Weight (t) | 2.18 | 2.9 | 4.25 | 4.58 | 5.58 | 6.5 |

| Feeding conveyor width (mm) | 350 | 350 | 350 | 450 | 470 | 550 |

| Feeding conveyor length (mm) | 4000 | 4000 | 4000 | 4000 | 6000 | 6000 |

| Discharging conveyor width (mm) | 600 | 600 | 600 | 900 | 900 | 1300 |

| Discharging conveyor length (mm) | 10000 | 10000 | 10000 | 10000 | 10000 | 10000 |

| Delivery | 1x20'GP | 1x20'GP | 1x20'GP | 1x20'GP | 1x40'HQ | 1x40'HQ |