The Hongxing Horizontal Grinder is used for processing items such as,wood logs, wood pallets, formworks, crop stalk,green waste, industrial wood trash and tree bark. These items are to be recycled into fine granules for the preparation of manufacturing new production materials. The Horizontal grinder may be called a wood crushing machine,wood chips making machine, wood shredder, wood chipper, or multifunction industrial waste disposal equipment. The names depend on what the machine is used for. The horizontal grinder is mainly used in biogas, biomass power, biofuel, industrial recycling, compost, engineering wood and fiberwood panel.

The horizontal grinder features

1)Apron conveyer for safety purposes

2) Automatically adjustable material feeding system which is to be changed by the grinding machine present grinding capability. The materials feed can be quick loading or slow changing depending on the controlling order feedback from the grinding part of the grinder by pr rate according of the main motor, avoiding idle running

3) With experienced design and machine parts the grinder possesses high throughput capacity and produces high quality chips

Application

The horizontal grinder is widely used for grinding wood, plywood trim, crop stalks slabs, battens, straws, industrial wood or plastic waste for the purpose of crushing.

Optional Configurations

1. Cutting knives quantities of grinding machine

2. Mesh size of screen

3. Input and out pout production capacity

4. Electric Power

Component

1. Feeding Conveyor of the grinding machine

Features:

Link-joint type

Material is high manganese steel

Long service life

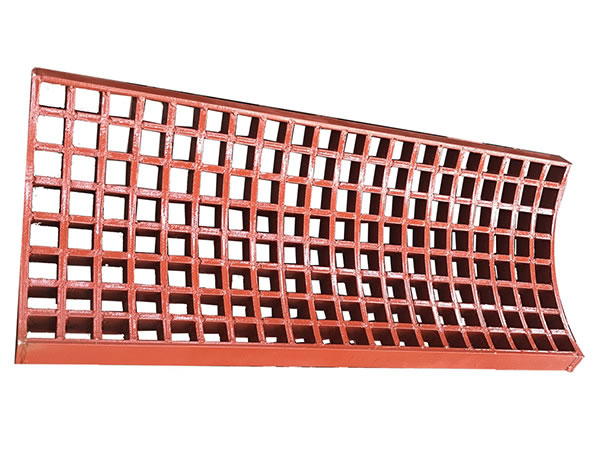

2. Screen of this horizontal grinder

High strength steel

Stereoscopic welded

Verydurable

customized screen size

3. Cutting Blade knives of this grinder

Material is H13

Interchangeable

Easy to change

Long service life

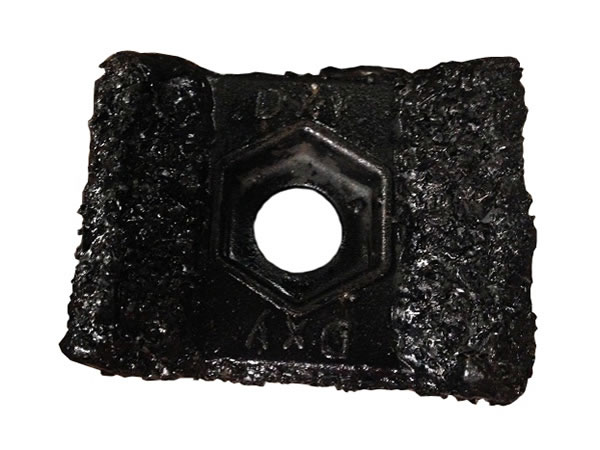

4.Hammering part of this grinder

Used alloy steel No.YT15

the hardness of hammer of this grinder has a long lifespan and is designed to be easily replaced.

5. Operating Control Cabinet

The operating control cabinet is assembling the function controller together

It is both convenient and safe for use by operators.

6. Other System

To be easy to check and replace cutting knives and screening sheets

Adjustable feeding rollers.

| Type | HX400A-B | HX400C-D | HX1250-500 | HX1400-500 | HX1400-700 | HX1400-800 | HX1400-1000 | HX2000-1000 |

| Rotor diameter (mm) | 650 | 650 | 800 | 800 | 960 | 1050 | 1300 | 1400 |

| Rotational speed (rpm) | 650 | 650 | 650 | 760 | 900 | 900 | 960 | 432 |

| Rotor type | 3 blades rotor | 3 blades rotor | 4 blades rotor, 8 pieces of blades | 4 blade rotor, 8 pieces of blades | 6 blades rotor, 12 pieces of blades | 6 blades rotor, 12 pieces of blades | 6 blades rotor, 12 pieces of blades | 6 blade rotor, 24 pieces of blades |

| Screen mesh shape and size (mm) | Round or hexagon, 60mm | Round or hexagon, 60mm | Round or Hexagon, 60mm | Round or Hexagon, 60mm | Round or Hexagon, 60mm | Round or Hexagon, 60mm | Round or Hexagon, 60mm | Round or Hexagon, 60mm |

| Feeding power (kw) | 7.5+4 | 7.5+5.5 | 11 + 7.5 | 11 + 7.5 | 11 + 7.5 | 11 + 7.5 | 15 + 11 | 15+15+11 |

| Hydraulic control power (kw) | 1.5 | 3 | 3 | 3 | 4 | 4 | 5.5 | 5.5 |

| Main motor power (kw) | 90 | 110 | 160 | 200 | 250 | 250 | 315 | 400 |

| Discharging power (kw) | 3+3 | 3+3 | 4 + 5.5 | 4 + 11 | 5.5 + 11 | 5.5 + 11 | 7.5 +15 | 7.5 +15 |

| Input conveyor length (mm) | Belt conveyor 5000mm | Belt conveyor 5000mm | 4000mm | 4000mm | 6000 mm | 6000 mm | 6000 mm | 6000 mm |

| Output conveyor length (mm) | 10000 mm | 10000 mm | 10000 mm | 10000 mm | 10000 mm | 10000 mm | 10000 mm | 10000 mm |

| Chips size (mm) | 30-50 | 30-50 | 30-50 | 30-50 | 30-50 | 30-50 | 30-50 | 30-50 |

| Throughput (t per h) | 6-8 | 8-10 | 10-12 TPH | 12-15 TPH | 15-20 TPH | 20-25 TPH | 30-35 TPH | 35-40 TPH |

| Input size (mm) | 700-400 mm | 1000-400 mm | 1250-500 | 1400-500 mm | 1400-700 | 1400-800 mm | 1400-1000mm | 2000-1000mm |

| Size (m) | 7 x 2.3 x 2 | 8.2 x 2.3 x 2 | 7.5 x 2.8 x 2.4 | 7.3 x 3 x 2.6 | 9.6 x 3 x 3.1 | 9.9 x 3 x 3.3 | 11 x 3 x 3.6 | 11 x 3.4 x 3.9 |

| Weight (t) | 6.8 | 8 | 15 | 16 | 24 | 26 | 32 | 40 |

| Packing | 1x40'HQ | 1x40'HQ | 1 x 40' FR | 1 x 40' FR | 1 x 40' FR+ 1x 20'GP | 1 x 40' FR+ 1x 20'GP | 1 x 40' FR+ 1x 20'GP | 1x40'FR + 1x40'OT |

Brief

We are a leading bio-industry and recycling industry equipment and machine manufacturer for businesses engaged in biomass, biogas, industrial waste recycling, and artificial wood board etc.. We offer these businesses the tree barking machine, wood crushing grinder, wood chipper and hammermill. Hongxin is an experienced and trustworthy horizontal grinder manufacturer.